Solid Mechanics¶

Strong Form¶

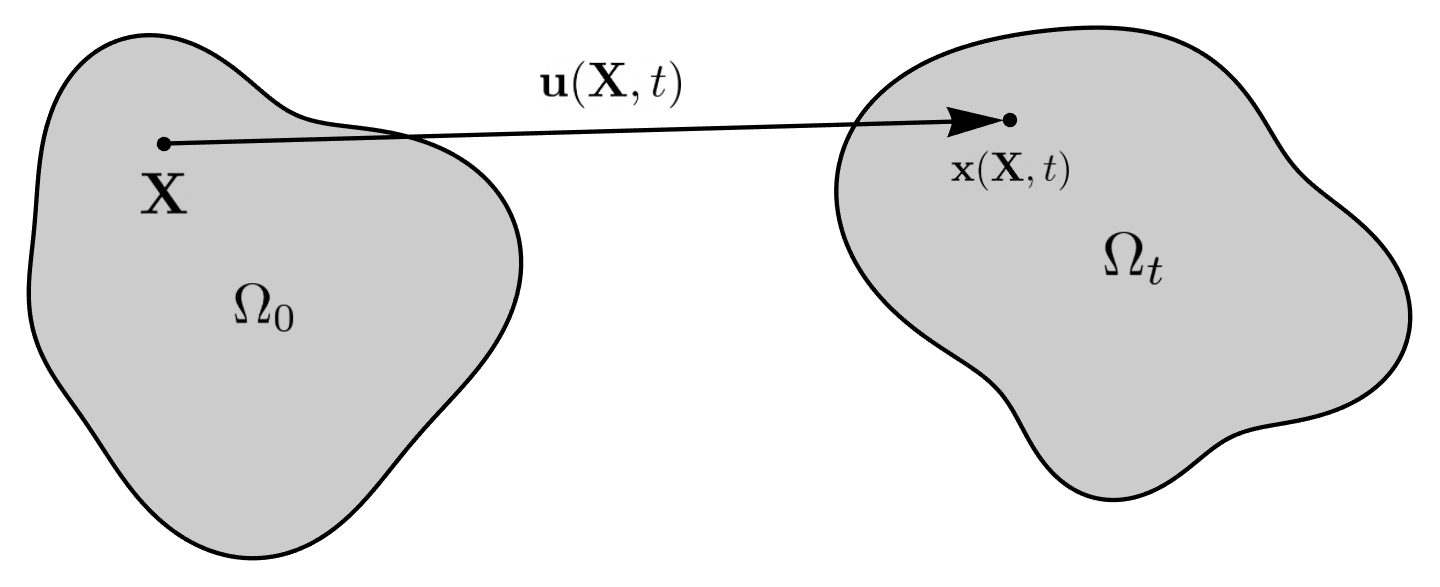

Consider the kinematics of finite deformation

where \(\mathbf{x}(\mathbf{X}, t)\) is the current position of a point originally located at \(\mathbf{X}\) in the undeformed (or reference) configuration. This motion is also commonly described in terms of the displacement

An important quantity characterizing this motion is the deformation gradient

We also define the internal forces due to deformation in the solid in terms of the Cauchy stress \(\mathbf{\sigma}\). If the deformed body is cut by a surface with normal vector \(\mathbf{n}\), the resulting traction vector \(\mathbf{t}\) is defined as

This stress is taken here as a function of the deformation gradient \(\sigma = \sigma(\mathbf{F})\) by the appropriate hyperelastic constitutive (material) model. The conservation of angular momentum implies this stress tensor must be symmetric, i.e. \(\sigma = \sigma^T\). We can then use the conservation of linear momentum to formulate the boundary value problem

where

and \(\nabla_\mathbf{x}\) implies the gradient with respect to the current (deformed) configuration.

Weak Form¶

Multiplying the PDE by a vector-valued test function \(\delta \mathbf{v}\) and integrating by parts yields the weak form

where

and \(\Omega\) is the current (deformed) configuration. In mechanics, the weak form is often referred to as the principle of virtual power. As Serac uses hyperelastic models, it is convenient to write this equation in the reference (undeformed) configuration

where \(\nabla_X\) is the gradient with respect to the reference (material) coordinates.

Material Models¶

Serac currently is restricted to hyperelastic material formulations, i.e. materials that behave in a reversibly elastic fashion under large deformations. Mathematically, this implies they are derived from a strain energy density function \(W=W(\mathbf{F})\). It can be shown that

where

is the first Piola-Kirchhoff stress. Serac currently only has two material models. First, a neo-Hookean material where

and \(\mu\) and \(K\) are the shear and bulk modulus, respectively. This definition also implies that the 2D simulations are using a plane strain assumption. The second model is a small strain isotropic linear elastic material where

and \(\epsilon\) is the linearized strain tensor. Note that this model is only valid for small strains where the neo-Hookean model is nearly equivalent. It is included mostly for testing purposes.

Discretization¶

We discretize the displacement field using nodal shape functions, i.e.

where \(\mathbf{u}^a\) are the degrees of freedom. We can then calculate the deformation gradient by

and substitute these quantities back into the weak form to obtain the vector-valued discrete residual equation

where \(\mathbf{t}^*\) is the traction applied in the reference configuration.

Optionally, we allow disabling the geometric nonlinearities by setting \(\mathbf{F} = \mathbf{I}\) everywhere in this residual evaluation except for the material response (stress) function.

Performing these integrals yields the discrete equations

where

This discrete nonlinear second order ODE system can now be solved using the selected linear algebra methods.

Material Parameters¶

Material models in serac may use different parameters for describing elastic properties. Specifying any two of these parameters lets you calculate the rest. The tool below can be used to perform these conversion calculations (assuming 3D):

Bulk Modulus (K)Young's Modulus (E)

Lamé's First Parameter (λ)

Shear Modulus (G, μ)

Poisson's Ratio (ν)

J2 Linear Hardening Parameters¶

The hardening constants, \(H_i, H_k\), in our J2 material model describe the extent to which the yield surface dilates and translates, respectively, when undergoing plastic deformation. The following animations illustrate the evolution of the yield surface and stress-strain relationship when subjected to cyclic strain, for different choices of \(H_i, H_k\).

"Perfectly Plastic" response: zero isotropic and kinematic hardening

isotropic hardening only

kinematic hardening only

isotropic and kinematic hardening

Contact Mechanics¶

When two surfaces on \(\Omega\) (the current configuration of the simulation domain) come into contact, an additional term in the weak form is needed to prevent their interpenetration. For contact enforcement without friction, the mechanical energy from contact is

where

Using the common surface, \(\Gamma_C\), the contact energy can be simplified to a single term:

where \(g(\bar{\mathbf{x}}) := \mathbf{n}(\bar{\mathbf{x}}) \cdot \bigl( \mathbf{x}_1 (\bar{\mathbf{x}}) - \mathbf{x}_2 (\bar{\mathbf{x}}) \bigr)\) is the gap normal. Taking variations of this with respect to displacement leads to the contact term in the weak form.

Mortar Contact¶

While notionally straightforward, the complexity (both in mathematical derivation and computation) of accurately computing the variation of the contact energy leads to many different simplifications and approximations in actual contact algorithms. Serac uses the mortar contact method in the Tribol interface physics library for contact enforcement. In Tribol, mortar contact enforcement is implemented following Puso and Laursen (2004). Therein, contact constraints are only satisfied in the normal direction, enabling constraints that enforce either frictionless contact (inequality constraints) or tied contact in the normal direction (equality constraints).

Mortar methods are defined by introducing an approximation of the pressure field with \(n\) basis functions \(N^a(\bar{\mathbf{x}})\) for \(a = 1, \dotsc n\) and \(n\) scalar coefficients \(p^a\) for \(a = 1, \dotsc n\),

allowing the contact energy expression to be simplified to

where \(\tilde{g}^a(\bar{\mathbf{x}}) = \int_{\Gamma_C} N_I(\bar{\mathbf{x}}) g(\bar{\mathbf{x}}) \, dA\). For frictionless contact, satisfaction of the Karush-Kuhn-Tucker (KKT) conditions that define the contact inequality constraints are then done discretely on the coefficients:

Discrete satisfaction of the inequality constraints (or equality constraints for tied contact in the normal direction), as opposed to e.g., pointwise satisfaction at the quadrature points, gives LBB stability, enabling exact solution of the pressure field by explicitly solving for the Lagrange multipliers in the resulting saddle point system. Additionally, mortar methods give optimal rates of convergence (when not limited by solution regularity) and give exact satisfaction of the contact patch test.

In Puso and Laursen (2004), the following choices are made for the quantities defined in the contact energy:

\(\mathbf{n}(\bar{\mathbf{x}}) := \mathbf{n}(\mathbf{x}_1)\) is a nodally interpolated, continuous field defined in terms of \(\Gamma_C^1\) where nodal values are determined by averaging normals evaluated at the nodal location in each element that is connected to the node.

\(\Gamma_C\) is defined for each pair of elements in contact by a multi-step process. First, a plane is defined on the element in the pair on \(\Gamma_C^1\) by the point at the element center and the nodally interpolated normal vector \(\mathbf{n}(\mathbf{x}_1)\) evaluated at the element center. Next, the nodes from each element are projected onto the plane and the overlap polygon is computed. The overlap polygon defines \(\Gamma_C\) for the element pair.

The surface \(\Gamma_C\) also defines the maps \(\mathbf{x}_1(\bar{\mathbf{x}})\) and \(\mathbf{x}_2(\bar{\mathbf{x}})\) via the projection of the nodes to the plane normal to the center of the element on \(\Gamma_C^1\).

\(p(\bar{\mathbf{x}})\) is an \(H_1(\Gamma_C^1)\) field defined on the nonmortar surface using the same discretization as the position and displacement fields.

Additionally, the definition of \(\tilde{g}^a\) is modified to

which does not affect the smoothness of the solution since \(\mathbf{n}(\mathbf{x}_1) \in {C^0}^\text{dim}(\Gamma_C^1)\) is nodally interpolated.

The expression for contact force is simplified through the assumption that terms that contain \(\tilde{g}(\bar{\mathbf{x}})\) only contribute minimally and are ignored. Note that neglecting these terms affect angular momentum conservation and energy conservation since the formulation is not variationally consistent. After introducing finite element approximations for \(\mathbf{x}_1\) and \(\mathbf{x}_2\), the nodal contact forces are

where \(\mathbf{f}_I^a\) is the force vector on node \(a\) of surface \(\Gamma_C^I\) for \(I=1,2\) and \(N_I^a(\bar{\mathbf{x}})\) is the basis function associated with node \(a\) of surface \(\Gamma_C^I\) for \(I=1,2\). In the above equation, \(\int_{\Gamma_C} N_1^b(\bar{\mathbf{x}}) N_I^a(\bar{\mathbf{x}}) \, dA\) is usually referred to as the mortar matrix. In Serac, the pressure degrees-of-freedom can be determined by one of two ways:

by introducing Lagrange multipliers as unknowns and explicitly solving for them or

by using a penalty proportional to the gap: \(p^b = \kappa \tilde{g}^b\).

The tangent is computed by taking variations of the force with respect to the displacement (and the pressure when solving for Lagrange multipliers). Similar to taking variations of the contact energy, taking variations of the contact force is a difficult, time consuming task, both computationally and mathematically. While Puso and Laursen (2004) present a consistent tangent, the tangent implemented in Tribol is only an approximation. Terms where \(\tilde{g}(\bar{\mathbf{x}})\) is present are assumed to be \(\approx 0\). As a result, quadratic convergence in Newton iterations is not expected when contact terms are included in the weak form.